Hi all.

I have been using my old 7' box trailer for years to go camping since we out grew, "Just the two of us a tent and the Esky" All we did was add 1 kid!

Anyway it has given up the ghost and I have decided to build exactly what i think it should be.

Basically what i am going to do is build a smaller trailer with more clearance and the same wheels and tyre size as the GU. Fit is out with water tanks, kitchen and later a roof top tent or camper tent.

I've got most of the design sorted, (I think!) but I am struggling with the clearance of the Axle from the Frame. I am taking inspiration from the Aus Army trailers with a single beam, (CHS in their case) that runs form the hitch to the tail. The problem is to get the ride height reasonable, there is not a lot of clearance, (IMO) between the axle and the "spine".

So to get me started, my question is; How much clearance would be required between the axle and the chassis of a trailer? (Or how much travel can I expect to see?)

I know this will largely depend on the weight, spring size, axle size....... But i am looking for a starting point.

Basic details are, 750kg 4 leaf slipper springs and 390mm round axle. (Suspension and axle are being salvaged from my rusted 7' to start with!)

Any feedback would be greatly appreciated.

Cheers

Glenn

scratch built off road trailer

Moderators: krp102, Coxy68, robcaz

Re: scratch built off road trailer

Hi Glenn,

You will find the trailer will be plenty strong enough for your needs by taking the A frame from just in front of the spring hangers.

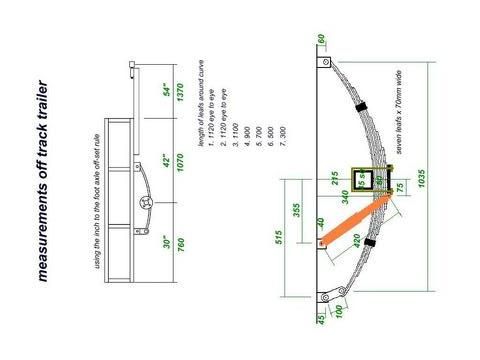

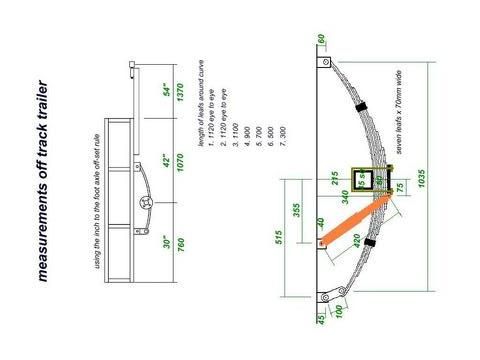

While our Track Trailer Eagle is heavier than what your design is Tare 730kg & ATM 1300kg the suspension is from 60 series Landcruiser leafs comprising of seven leaf springs by 70mm wide with an eye to eye measurement of 1040mm.

The measurement from the 45mm square axle to the chassis is 215mm

The Guiding Star 6foot x 4foot trailer chassis is fabricated from 60x60x3 RHS, the cross members 50x50x3 RHS and the A frame from 75x50x3 RHS. It has been on some very rough roads over the 23 years we have owned it & has never fallen apart.

There are several points & links you may be interested in the article I put together on what makes a good off road trailer http://www.campertrailers.org/off_road_trailer.htm

The main thing is to match your intended maximum trailer weight to the leaf springs. Also don't forget a good rule of thumb is to have around 10% to 15% of the trailers weight on the towball. which will ensure it has a good forward tracking motion.

An old mate of mine used to build box trailers. His rule of thumb was to set the axle to the rear from the centre of the trailer an inch to the trailers feet in length, that is if the trailer was 6 foot the axle would be move towards the rear 6 inches to give the trailer a good ball weight with an even load. If you are adding tool boxes & jerrys, spare wheels etc to the draw bar then the axle must me moved towards the centre to compensate for that weight & to get the 10% to 15% on the ball.

The axle size can be worked out by the trailers GTM http://www.campertrailers.org/axles_bearings.htm

The axle spindle load is governed by the bearing size.

Hope this helps.

You will find the trailer will be plenty strong enough for your needs by taking the A frame from just in front of the spring hangers.

While our Track Trailer Eagle is heavier than what your design is Tare 730kg & ATM 1300kg the suspension is from 60 series Landcruiser leafs comprising of seven leaf springs by 70mm wide with an eye to eye measurement of 1040mm.

The measurement from the 45mm square axle to the chassis is 215mm

The Guiding Star 6foot x 4foot trailer chassis is fabricated from 60x60x3 RHS, the cross members 50x50x3 RHS and the A frame from 75x50x3 RHS. It has been on some very rough roads over the 23 years we have owned it & has never fallen apart.

There are several points & links you may be interested in the article I put together on what makes a good off road trailer http://www.campertrailers.org/off_road_trailer.htm

The main thing is to match your intended maximum trailer weight to the leaf springs. Also don't forget a good rule of thumb is to have around 10% to 15% of the trailers weight on the towball. which will ensure it has a good forward tracking motion.

An old mate of mine used to build box trailers. His rule of thumb was to set the axle to the rear from the centre of the trailer an inch to the trailers feet in length, that is if the trailer was 6 foot the axle would be move towards the rear 6 inches to give the trailer a good ball weight with an even load. If you are adding tool boxes & jerrys, spare wheels etc to the draw bar then the axle must me moved towards the centre to compensate for that weight & to get the 10% to 15% on the ball.

The axle size can be worked out by the trailers GTM http://www.campertrailers.org/axles_bearings.htm

The axle spindle load is governed by the bearing size.

Hope this helps.

happy camping

Rob & Carol

Australian CamperTrailers Group co-owner

We're just two lost souls swimming in a fish bowl, year after year

Rob & Carol

Australian CamperTrailers Group co-owner

We're just two lost souls swimming in a fish bowl, year after year

Re: scratch built off road trailer

Thanks for that,

My Initial design only has about 50mm clearance above the axle in the centre..........

Looks like back to the drawing board!

Cheers

My Initial design only has about 50mm clearance above the axle in the centre..........

Looks like back to the drawing board!

Cheers