|

installing

lithium batteries

the latest in battery technology

lithium batteries in place in battery

compartment

We recently upgraded from our four and a half

year old Vista RV Crossover to a new Crossover XL. As part of the

process I spent around three months investigating battery options.

The original Gel batteries had done a good job, but I thought I

should check out some of the newer options. I looked at Lead Crystal

batteries and Lithium cells. My final decision was to opt for

Lithium cells.

theory

Lithium cells are around half the weight of lead

batteries, yet can be safely discharged to 20% State of Charge

(SOC), as opposed to only 50% SOC for lead batteries. This means

Lithium batteries can give 160 useable Amp hours out of 200 Amp

hours total instead of 100 Amp hours from the same 200 Amp hours of

lead batteries, a 60% gain.

They also maintain their voltage down to 20% SOC

so things like fridges keep working efficiently. The voltage of a

lead battery drops off as the battery drains. Lithium cells can also

safely accept up to 1C (one times the rated Amp hours of the cell)

so, in this case, 1x100 = 100 Amps as a charging rate and can handle

high discharge rates as well, easily 100 Amps.

They are also very efficient at charging, almost

100%. The down side is the initial cost of roughly twice the same

nominal capacity Gel of AGM batteries. This however is offset by

their long life, usually 10 to 20 years.

There is much spirited – if not downright

vitriolic! – debate online as to how to go about setting up Lithium

cells. In the end, after talking to several suppliers, I opted to

get the cells and monitoring equipment from EV Works in Perth and

follow their advice. I put together a reasonably simple setup which

monitors individual cell voltages and automatically attempts to

rectify any problems.

putting it all

together

Lithium cells come as individual 3.7 Volt cells

with different Amp hour ratings. You can make up a “battery” out of

however many cells of the same Amp hour rating as you need to get

the voltage you need. To get a 12 Volt battery, you need four cells.

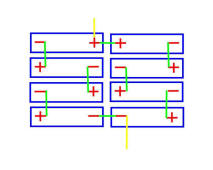

I decided to go with eight Winston 100 Amp hour cells, arranged as

two 100 Amp hour, 12 Volt batteries. I joined two sets of four cells

together in series in mirror image. The end positive and negative

terminals are then side by side and can be easily joined together in

parallel, giving 200 Amp hours at a nominal 12 Volts.

To monitor the individual cell voltages, I used a

pair of ZEVA BMM8 Battery Monitor Modules from EV Works. You need

one module per battery. These modules use a wire attached to each

positive terminal of a battery to monitor the voltages. You also

connect a negative wire to the module. The module can then monitor

each cell in a battery individually and detect if one cell is going

too high or too low in voltage. If this happens, a small solid state

relay on the circuit board is triggered, causing it to open. There

is one for high voltage, another for low.

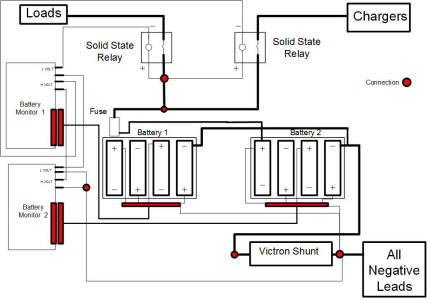

These relay outputs are, in turn, daisy chained,

high with high and low with low, over the two batteries. The cables

are then run to a pair of solid state relays, one connected to the

charger outputs and the other to the loads – fridge, lights, etc.

These relays will disconnect either the chargers or the load on the

batteries, depending upon the problem. If a cell is too high, the

chargers are disconnected, leaving the load still connected to draw

the voltage back down. If a cell is too low, the load is

disconnected, leaving the chargers connected to try to bring it back

up. Once the problem is fixed, the relay is reconnected

automatically.

I fitted a pair of 100 Amp solid state relays

from Jaycar. These were cost effective and have a very low current

demand. I made up a pair of wiring looms with four wires each, each

wire terminated with an 8mm eye terminal. The wires were from a Cat5

network cable with braided strands. The eye terminals were attached

to the positive posts of each cell, one loom per battery. The other

ends of the wires were soldered into the male plugs to connect to

the BMM8s.

I made a second set of positive terminal wires

running from both batteries into the electrical cabinet of the Vista

Crossover XL. These connect to a pair of plugs, one per battery,

which I can attach to a pair of Cell Log8s which give a readout of

each individual cell voltage when connected. This I did for peace of

mind – and because I am a technoweenie and I could! The Cell Log8s

came from Hobby King who have an Australian outlet.

A section of 12mm ply was fitted to the top of

the batteries to protect the terminals and to the front of the

batteries to allow attachment of the BMM8s. The batteries were

fitted into the battery compartment on the Vista Crossover XL and

secured in place with a ratchet strap running around the cells to

hold them together and another strap over the top to hold them down.

The BMM8s were screwed to the ply and then a clear cover was screwed

in place to protect them. I used a couple of clear plastic lids from

NARVA component boxes, but a piece of clear perspex would do.

Two positive cables were attached to the

battery’s common positive terminal, one running to the charger solid

state relay, one to the load one. One negative cable was attached

and it runs to the shunt for my Victron BM700 intelligent battery

monitor.

at first

The cables were then all attached and the system

commissioned. I discovered that the charge relay disconnected upon

commissioning. After checking I found out that Lithium cells, like

lead batteries, can hold a high residual charge – a “surface charge”

– when they are charged initially. I simply turned on a few LED

lights in the Vista Crossover XL for a while and the relay turned on

as the surface charge was taken off the cells. It worked as

advertised.

One of my biggest worries was finding appropriate

chargers. I spent a lot of time examining the specifications of some

very expensive chargers, several of which claimed to be ideal for

Lithium batteries. Upon much research I worked out that most of them

were not. After talking to people who install Lithium batteries for

a living, I worked out that charging is not such a problem after

all.

charging

Charging in the Vista Crossover XL is done by

three separate chargers. I have a Projecta 50 Amp AC-DC charger to

handle charging from 240 Volts when it is available. This charger is

rated to 0.5C of the 100 Ah cells, so is very safe for a fast charge

– under four hours if the batteries were down to 20% SOC. I have it

as “Power Supply” so it delivers 13.8 Volts to the batteries. This

is considered a very safe charging voltage.

There is a Ctek D250S Dual to work as a DC-DC

charger when driving and as an MPPT solar controller for my two 135

Watt semi flexible portable panels. This charger is not user

configurable at all. It supplies 14.4 Volts as a bulk charge and

13.8 Volts as a float.

The third charger is a Projecta 20 Amp solar

controller to look after the 105 Watt fixed solar panel on the rear

of the XL. This panel can easily be removed to allow me to put it

out in direct sun. The charger is set to “Gel” so it supplies 14.2

Volts on bulk charge and 13.8 Volts as a float.

overview

The system is working well with all the cells

staying within 0.01 of a Volt of each other – a very good thing.

Losing 35 kilos and gaining 60 Amp hours is a wonderful thing!

The total cost, including monitoring hardware,

was around $1700 for 200 Amp hours, 160 Amp hours useable, with a

weight of around 30 kilograms. To get 160 useable Amp hours out of

lead batteries you would need roughly 300 Amp hours of capacity,

costing around $900 for good quality batteries and weighing around

100 kilograms.

links

EV Works

http://www.evworks.com.au

BMM8 module

http://www.evworks.com.au/zeva-8-cell-bat-monitor

Jaycar Solid State Relay

http://www.jaycar.com.au/Electromechanical-Components/Relays-%26-Accessories/Solid-State/Solid-State-Relay-4-32VDC-Input%2C-30VDC-100A-Switching/p/SY4086

Cell Log8

http://www.hobbyking.com/hobbyking/store/__44896__Cell_Log_8M_Cell_Voltage_Monitor_2S_8S_Lipo_AU_Warehouse_.html

|

|

|

|

two batteries made

up on the work bench |

individual cells in

a crate |

|

|

|

|

battery compartment |

|

|

how cells are

connected to make two batteries |

the three chargers

in the electrics cupboard |

|

|

|

circuit diagram |

Thanks to David Jones for this article

july

2015

|