I have just rebuilt my battery box and compressor box for the

Jeep making them easily removable as I only load them when

needed.

The battery box is a Hard

Korr heavy duty battery box, a strong and neat design. There are

two cigarette sockets and a twin USB socket. It also has 4x 50

Amp Anderson plugs, 3x grey and 1x black. I converted one of the

greys to red. It also has 1x 175 Amp Anderson plug and a master

switch. There is a readout LED panel for voltage and state of

charge which you turn on and off manually, so it is not on all

the time. The state of charge part is useless with Lithium

batteries.

It easily holds my Sentry

125 amp hour Lithium battery and I have packed it into place

inside the box. I have also fitted a Ctek D250S Dual DC to DC

charger inside the box, bolted to the lid inside. I disconnected

the built in Voltage Sensitive Relay and used the positive from

the black Anderson plug to connect to the alternator input on

the Ctek. I have a 6B&S lead with fuse running from the starter

battery, under the floor mats and the end - with a black

Anderson plug, which will also connect to a grey Anderson plug -

is stored behind the cargo flap across the back of the back

seat. I simply pull it out to connect to the battery box.

The red Anderson plug is

connected to the solar Input on the Ctek - I use red Anderson

plugs for all my unregulated solar connections and all my panels

are unregulated (do not have a regulator attached). I can easily

plug either of my 135 Watt or my 100 Watt solar panels to the

red Anderson plug to charge the battery through the solar

controller on the Ctek. I can even plug both 135 Watt panels to

it using a Y cable at the panel end.

That leaves two grey

Anderson plugs which are connected directly to the battery via a

circuit breaker and can be used for things like my fridge. The

fridge, by the way, is a Waeco 45 litre CFX and fits perfectly

between the door and the battery box.

There is a 175 amp

Anderson plug on the battery box. I use this to connect the

compressor as it has a peak current draw of 110 amps. The

compressor current drops to around 80 amps after the start up.

I can also use it to connect this battery to the car starter

for a jump start as I have made up a pair of crocodile clips on

a length of 6B&S cable with a 175 amp Anderson plug on the other

end.

The battery box with 125

amp lithium battery inside weighs in at 19 kilograms.

battery

box

|

|

|

the battery box |

Anderson plugs on end of battery box |

|

|

|

|

battery sitting inside the box |

underside of the battery box lid |

|

|

|

|

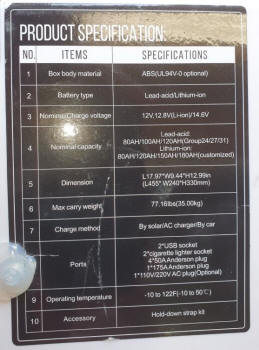

battery box specifications |

old battery box setup |

air

compressor

The compressor is a twin

cylinder Thumper Max from the 4WD Supercentre with a 300 litre

per minute rating. The previous air compressor was a Bushranger

Max Air. They are chalk and cheese. The Bushranger would take a

few minutes to pressurise the air tank and 8 metre hose. The

Thumper does it in around 30 seconds.

I used a 150 amp

automotive relay to turn the compressor off and on from the

driver's seat – the compressor has a pressure limiting switch

built in, so it automatically turns itself off and on with

pressure changes, the limits being off at 125 psi and on at 90

psi. I simply have a run of speaker wire from the relay to a

switch by my right knee to activate it. To connect/disconnect

the switch cable to the relay I used a pair of Deans plugs, very

popular with remote control aircraft people. It is rated to 60

amps so should handle the switching current, that way I can turn

it on and off from the driver’s seat and not have to access the

compressor’s own switch. I store the hose coiled up in a canvas

bag which I can either leave on top of the load in the back or

attach to the rear headrest and hang on the backseat backrest.

The 8 metres of hose easily reaches all the car and Crossover

tyres and I have an extra 4 metres that came with the compressor

and even has Nitto fittings to match my hose and fittings so I

can extend the hose to 12 metres and pump up other people's

tyres.

I have an 11 litre air

tank to maintain pressure in the system. It has an over

pressure release (150 psi), drain plug and pressure gauge

attached. A simple plywood casing I made up holds the compressor

and the air tank is bolted on top. The unit weighs in at 16

kilograms.

The wiring connected –

black 50 amp Anderson plug to the starter battery, grey 175 amp

Anderson plug to the compressor via the 150 Amp automotive

relay. The red Anderson plug is for unregulated solar and the

two spare grey Anderson plugs are for the fridge and anything

else I want to plug in.

The whole setup took

around a day to make up. It takes a few minutes to put it in

place and strap it all to the child seat restraints on the back

of the backseat. I only install it when needed so I am not

taking up space and carting 25 kilograms around when I don't

need it. The Lithium battery weighs less than half what the old

120 amp hour AGM weighed, has 60% more useable energy, charges

faster and maintains the Voltage down to 20% state of charge –

win, win, win and win.